Products

OEM China Tape To Fix Pipe Leaks - fix tape – ASN

OEM China Tape To Fix Pipe Leaks - fix tape – ASN Detail:

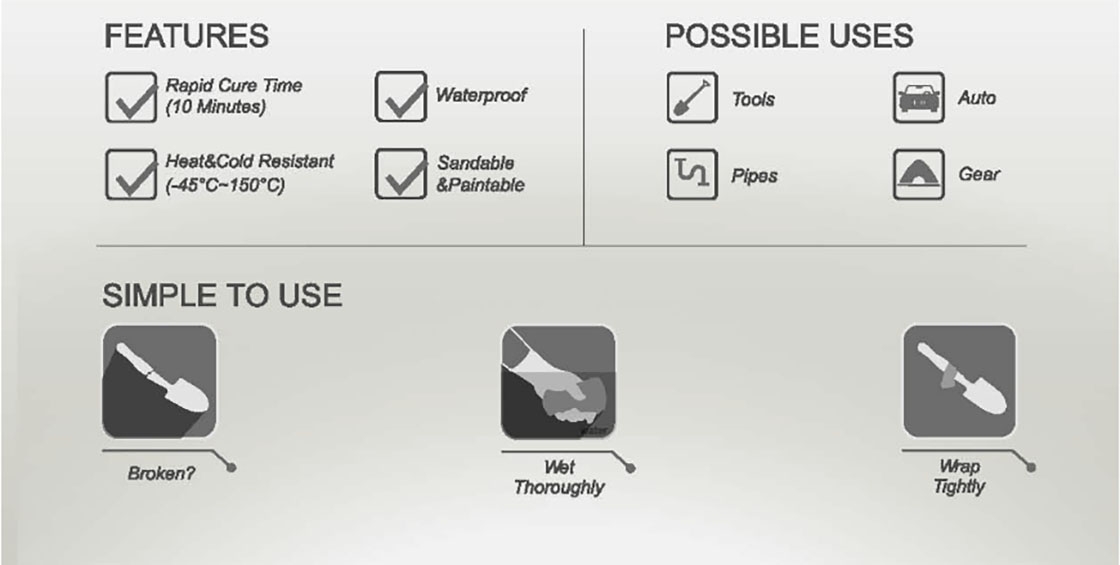

Features:

• Catalyst: Water

• Resin Makeup: Polyurethane

• Heat Resistance: 180°C

• Pressure: 2175 PSI

• Bonds: Copper pipe, PVC, polypipe, metal, fibreglass

• Set Time: 20– 30 minutes, sets under water

• Chemical resistance: Most diluted chemicals and fuels

1.Resists cold and hot temperatures

2.Easy to apply, no mixing or messy clean up

3.Resistan to water, acid, salts, or soil organics

4.Can be applied underwater or to wet surfaces

5.Quick, long term protective coating, ready for immediate service

6.Non-toxic and acceptable for portable water lines

Technical Data

♦ Useable life: 2-3 minutes, depending on temperature of water and pipework

♦ Intial cure time: 5 minutes

♦ Full cure time: 30minutes

♦ Shore D hardness: 70

♦ Tensile strength: 30-35Mpa

♦ Tensile modulus: 7.5Gpa

♦ Maximum service temperature: 180° C

♦ Pressure resistance:400 psi (Min wrapping 15 layers around cracked/leaking area)

Application

1. Once the leaking area is identified, shut down relevant pipes or hoses immediately. Prepare the surface by cle aning and roughening the pipe.

2.Put on enclosed latex gloves. Apply Steel Putty to the leak site and mould.

3.Open foil pouch and immerse bandage in temperate fresh water for 5~10 seconds.The entire contents must be used once the package is opened.

4. Apply around the damaged area extending up to 50mm either side of the leak to ensure complete coverage.

5. As curing begins once it is taken out of the water. Whilst wrapping, pull each layer tightly by using your hand to mould and squeeze the layers

together. Continue this action during and upon completion.

Packing & Shipping

Packing: Carton packaging

Delivry time: within 3 weeks from order confirmation date

Shipping: By sea/air/express

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for OEM China Tape To Fix Pipe Leaks - fix tape – ASN , The product will supply to all over the world, such as: Jamaica, Belgium, South Korea, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!